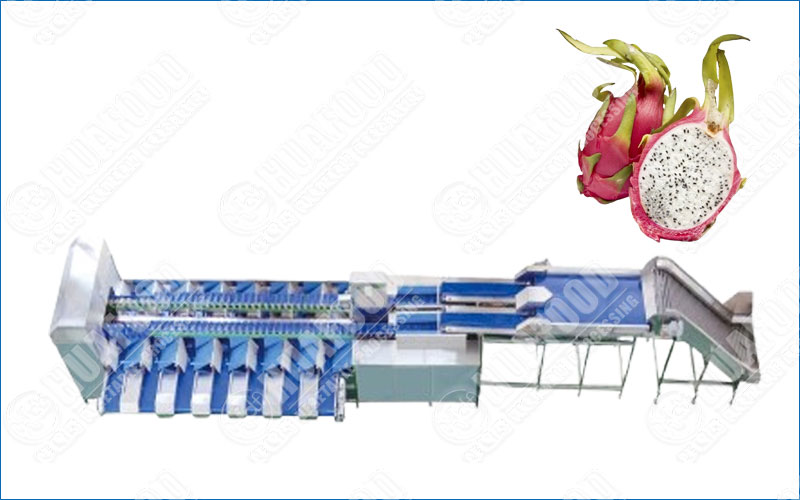

This Dragon Fruit Sorting Machine is specifically designed for pitaya sorting. It utilizes a dual-lane layout to achieve high-speed, high-capacity sorting. As a tropical fruit with delicate peels, irregular shapes, and wide variations in size, pitaya grading and handling before packaging are crucial. This fruit sorting machine aims to improve sorting efficiency and reduce the burden of manual sorting. Its automated dual-lane design meets the needs of large-scale pitaya sorting, thereby helping to achieve better quality and higher production capacity for export, wholesale, and retail.

Dragon fruit enters the equipment from the infeed buffer, where a conveyor system typically distributes the fruit evenly to two parallel sorting lanes.

In each lane, the fruit is presented individually or conveyed in a single file to avoid overlap and accumulation, ensuring accuracy in the subsequent weighing and inspection steps.

Prossimo, along conveyor belts or dedicated trays, the fruit passes through weighing modules, size inspection, or quality screening modules, where they are dynamically graded according to predefined criteria (such as weight range, size grade, and acceptable appearance). The equipment is compatible with dragon fruit weighing approximately 20-4000 G.

Based on the inspection results, the control system directs the fruit to the corresponding grading outlet. The discharge ports of each lane can operate synchronously, achieving high throughput in both lanes. Finalmente, the fruit is directed to different packaging sizes or grades.

The entire process design focuses on the unique characteristics of dragon fruit: its susceptibility to impact, squeezing, and soft skin. Perciò, the conveying, diversion, and guide rails feature cushioned, shock-absorbing, low-impact, and collision-free structures to minimize fruit damage during the sorting process.

Double Lane Parallel Sorting: The equipment provides two parallel lanes that can operate simultaneously, increasing overall production capacity.

High-Speed Precision Weighing and Grading Module: Integrates electronic weighing and size detection modules to accommodate a wide range of dragon fruit weight and size specifications.

Fruit-Protected Conveying Design: Designed to minimize damage to dragon fruit due to its soft skin and unique shape, the system utilizes a cushioning tray, low-impact conveying, and single-file arrangement.

Intelligent Control System and Visual Operation Interface: PLC or touchscreen control, multi-level settings, and support for data statistics and tracking analysis enhance operational convenience and system controllability.

Precise Sorting and Uniform Grading: Accurate weight and size detection ensures stable grading, contributing to standardized packaging specifications.

Easy Operation and Low Maintenance: The intelligent control system and modular design enable easy operation, short training cycles, and convenient maintenance.

Low Fruit Damage and Better Quality: The conveying and diversion system, specifically designed for the structural characteristics of pitaya, reduces collisions and squeezing, improving yield.

Significantly Improved Production Capacity: Simultaneous operation of two channels significantly increases processing capacity, meeting the needs of high-volume pitaya cultivation and packaging.

Accelerate the packaging and shipping process: Higher sorting efficiency means faster picking, confezione, and shipping, improving market responsiveness.

Reduce labor costs and defective product losses: Automated dual-lane sorting reduces the need for manual sorting, while lowering damage rates and reducing waste.

Improve product consistency and brand image: Dragon fruit with uniform grades and sizes benefits high-end markets and export channels, enhancing brand reputation.

Enhance overall production line flow and traceability: From weighing and grading to packaging and export, the intelligent system records data, facilitating process management and quality tracking.

In sintesi, the Fast Speed Dragon Fruit Sorting Machine with Double Lane is a highly efficient sorting machine specifically designed for pitaya, a high-value tropical fruit with irregular shapes, diverse sizes, and delicate skin. Its dual-lane high-speed structure, high-precision weighing and grading, fruit-friendly conveying design, and intelligent control system help you achieve faster returns, lower waste, greater packaging consistency, and better control of labor costs.

If you would like to learn more about this machine's specifications, number of grading lanes, capacity integration, service options, and pricing details, please contact us online today. Our professional team will provide detailed product information, customized configuration recommendations, and technical support. We look forward to hearing from you and working together to usher in a new era of greater efficiency and intelligence for your pitaya sorting production line!

Lavatrice per verdure

Lavatrice per verdure

WhatsApp

Scansiona il codice QR per avviare una chat whatsapp con noi.