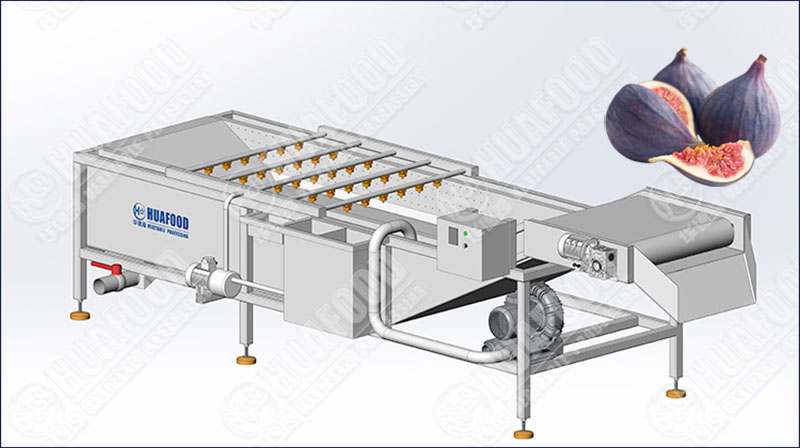

La lavadora de higos industrial con esterilizador de ozono es un dispositivo industrial diseñado específicamente para la limpieza, eliminar las impurezas, y higos esterilizantes. Integra la limpieza de burbujas de aire, pulverización de alta presión, y tecnologías de esterilización de ozono para centrarse en la limpieza de la superficie y mejorar la seguridad de las higos. Es adecuado para las empresas de procesamiento de higos, Fabricantes de frutas secas, y procesos de pretratamiento en líneas de producción de puré de higos/mermelada.

Construido de SUS304 (u SUS316L opcional) acero inoxidable, El equipo distribuye uniformemente higos en el tanque de lavado. Una bomba de aire genera burbujas para volar los higos, Mientras que un sistema de pulverización de alta presión los enjuague desde múltiples direcciones. Ozono (O₃) se inyecta simultáneamente en el agua circulante, Degradación de los residuos de pesticidas y las bacterias y microorganismos superficiales de la superficie. Un sistema de filtración recupera las impurezas flotantes, y las aguas residuales se asientan y se descargan para su reutilización como agua limpia. Todo el proceso es suave y eficiente, sin dañar la piel del higo.

Un sistema de doble limpieza de burbujas de aire y spray de alta presión elimina a fondo la suciedad, huevos de insectos, y polvo de la superficie del higo, No dejando esquinas intactos.

Un sistema de generación de ozono incorporado combina ozono con agua circulante para crear un entorno altamente oxidante, Degradación de residuos de pesticidas y esterilización.

La máquina está construida de acero inoxidable de grado alimenticio y admite parámetros personalizables (capacidad, tamaño, relación de ozono, etc.), con un diseño flexible para instalación móvil o fija.

El sistema de filtración de circulación de agua separa automáticamente las impurezas flotantes, y las aguas residuales se eliminan a través del filtro para reutilizar, Conservar el agua y proteger el medio ambiente.

Limpieza completa sin dañar la fruta: Una combinación de volteo y pulverización de burbujas asegura una superficie limpia y higos intactos.

Costos reducidos de agua y mano de obra: Las funciones de filtración y circulación reducen el consumo de agua, Mientras que la operación automatizada reduce la dependencia laboral y los costos laborales.

Estándares mejorados de seguridad alimentaria: La esterilización de ozono elimina efectivamente los patógenos, hongos, y residuos de pesticidas, Asegurar que los productos cumplan con los requisitos regulatorios de exportación y seguridad alimentaria.

Altamente modular y personalizable: Una amplia gama de capacidades de producción permite configuraciones personalizadas y características adicionales. (tales como ruedas y sistemas de control) para satisfacer las necesidades del cliente.

Elimina las bacterias y los residuos, Mejorar la seguridad del producto y la vida útil.

Fácil de operar y mantener, Adecuado para uso en línea en medio- a plantas de procesamiento de higos a gran escala.

Mantiene el color aparente y la integridad estructural de las Figs., Mejorar la calidad de la apariencia de las ventas y la satisfacción del cliente.

Se mejora la eficiencia general, el trabajo se salva, y la reelaboración se reduce, resultando en una mayor productividad y rendimientos económicos para los clientes.

En breve, La lavadora de higos industrial con esterilizador de ozono combina sin problemas una limpieza eficiente, tratamiento suave, y poderosas tecnologías de esterilización, Diseñado específicamente para la industria de procesamiento de higos. Esto mejora significativamente la limpieza, seguridad, y la competitividad del mercado de los productos de higos. Si procesando higos frescos, higos secos, o higos en puré, Sirve como un equipo frontal clave, Mejorar la eficiencia de la línea de producción y garantizar los estándares de seguridad alimentaria.

Contáctenos en línea para obtener más información sobre las especificaciones de equipos, opciones de capacidad, opciones de personalización, y citas. Deje un mensaje ahora y permítanos proporcionar soporte profesional y soluciones confiables para su negocio de procesamiento de higos!

Lavadora de verduras

Lavadora de verduras

WhatsApp

Escanee el código QR para iniciar un chat de WhatsApp con nosotros.