The herbs washing machine is used to clean large volumes of clean freshly harvested herbs—such as mint, basil, lavender, rosemary, and coriander by removing soil, dust, pesticide residues, insects, and other impurities without damaging delicate leaves or stems. It employs a combination of water spray, bubble agitation, and sometimes rotating drums or mesh conveyors to ensure thorough yet gentle cleaning, preserving leaf integrity and active compounds. These machines serve industries ranging from culinary herb producers to pharmaceutical and cosmetic manufacturers, delivering consistent product quality, higher throughput, and reduced labor compared to manual washing methods.

-

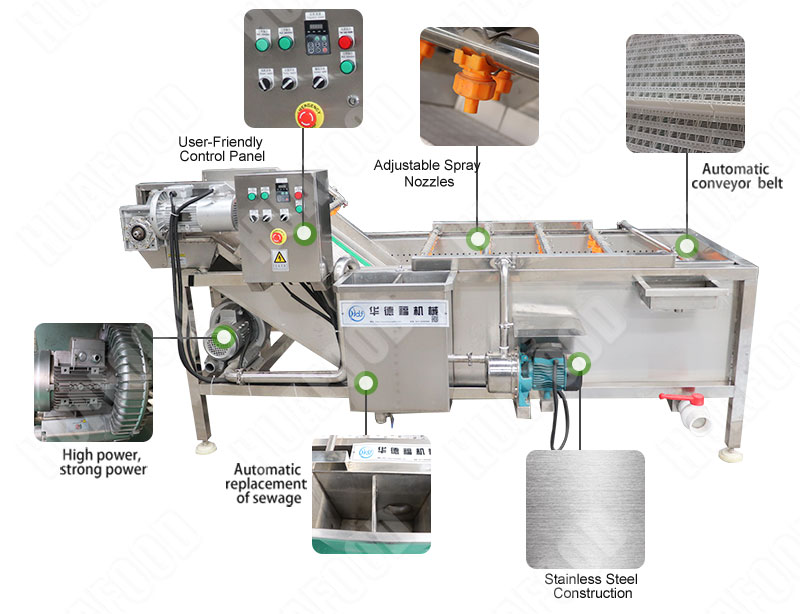

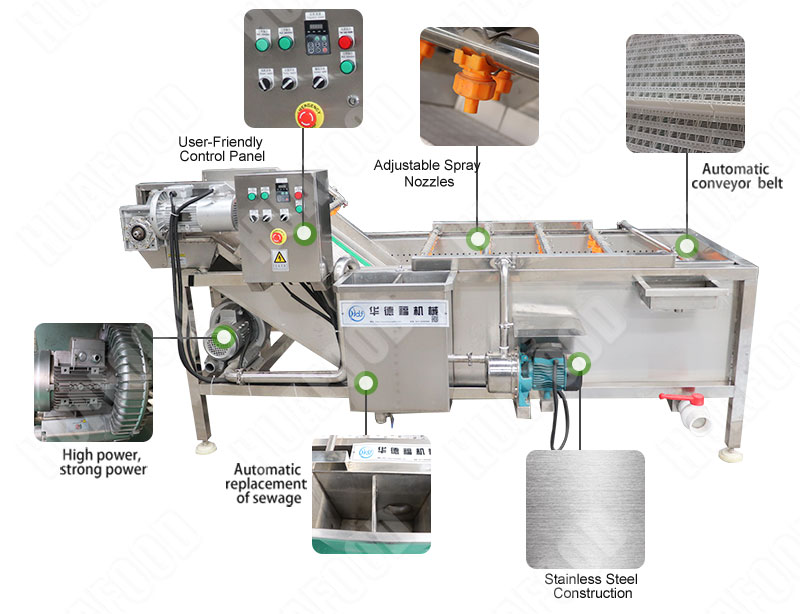

Stainless Steel Construction: All contact parts are made from food-grade 304 stainless steel, ensuring corrosion resistance and easy sanitation.

-

Adjustable Spray Nozzles: Precision nozzles offer customizable water pressure and angle, targeting hard-to-reach surfaces for a consistent clean.

-

User-Friendly Control Panel: Intuitive touchscreen interface allows operators to set wash cycles, adjust bubble intensity, and monitor flow rates.

- Bubble Agitation Technology: Advanced air bubble generation creates uniform turbulence, dislodging dust, debris, and residues without compromising leaf integrity

- High-Capacity Operation: Designed to handle 500 kg/h, the Automatic Herbs Leaves Bubble Washing Machine supports continuous, uninterrupted processing for high-volume production lines.

-

Labor Savings: Automated wash cycles and low-maintenance design reduce manual handling, freeing staff for higher-value tasks.

- Reduced Water Consumption: Optimal nozzle design and recirculation system cut water usage by up to 40%, supporting sustainable operations.

- Gentle Cleaning: Bubble wash minimizes mechanical friction, preserving the delicate cell structures of herbs and leaves, which translates to higher product integrity.

-

Versatile Application: Equally effective on a broad range of botanicals—including mint, basil, lavender, and rosemary—this herbs washing machine adapts to diverse product lines.

- Labor & Cost Savings: Automation reduces manual handling, lowers water use, and minimizes downtime for faster ROI;

- Enhanced Quality: Uniform, damage-free cleaning preserves visual appeal, aroma, and active compounds, commanding premium prices;

- Increased Throughput: Capacities range from several hundred to over a thousand kilograms per hour, supporting large-scale production;

- Compliance & Safety: Meets international food and pharmaceutical standards (CE, FDA, GMP), ensuring end-product safety and market access;

Food & Culinary: Ensures hygiene and taste integrity of leafy herbs before drying, packaging, or infusion;

Medicinal Herbs: Removes pesticide traces and microbial loads to meet GMP and CE/FDA standards for herbal medicines;

Cosmetics & Aromatherapy: Cleans botanical ingredients used in essential oils, creams, and soaps, preserving color and aromatic compounds;

-

Compliance Certification: CE and FDA approvals certify that the washing process meets international food safety standards.

-

Case Study: A Mediterranean herb farm saw a 25% reduction in damaged leaves and a 15% decrease in water usage within the first month of operation.

- Industry Adoption: Leading herb producers in Europe and North America report a 30% uplift in throughput after integrating bubble washing technology.

In summary, the Automatic Herbs Leaves Bubble Washing Machine 500 kg/h stands out as a robust, eco-friendly, and user-centric solution for bulk herb cleaning. By leveraging gentle bubble agitation and precision spraying, this herbs washing machine ensures top-tier product quality, operational efficiency, and sustainable resource use. Ready to upscale your herb cleaning process? Leave us an online message now to get detailed equipment specifications and a customized quotation!

Vegetable washing machine

Vegetable washing machine

WhatsApp

Scan the QR Code to start a WhatsApp chat with us.