Podemos fornecer profissionais de negócios de fabricação de gengibre em todo o mundo, A linha de produção automática de gengibre em pó é usada para processar 500 kg de gengibre fresco em pó de gengibre por hora através de lavagem de gengibre fresco, fatiar, secagem,pó, Embalagem ECT. De lavagem e descascamento à moagem e embalagem, Esta linha de produção automatizada simplifica todo o processo, Garantir pó de gengibre de alta qualidade com trabalho mínimo. O processo é altamente escalável, tornando-o adequado para empresas de pequena escala e grandes fabricantes. Também é adequado para a açafrão em pó de fabricação.

Como produzir pó de gengibre

O processo de produção de gengibre em pó inclui principalmente:Recepção de gengibre fresco → Classificação de gengibre & Armazenar → Lavando & Peeling → Fatia de gengibre & Secagem → Moagem → Peneirando & Embalagem

Recepção de gengibre fresco

Receba raízes de gengibre frescas, realizar inspeção preliminar e remover impurezas.

Classificação de gengibre & Armazenar

Classificando raízes de gengibre para garantir que apenas as raízes de gengibre de alta qualidade entrem na linha de processamento, e depois armazene -os para processamento adicional.

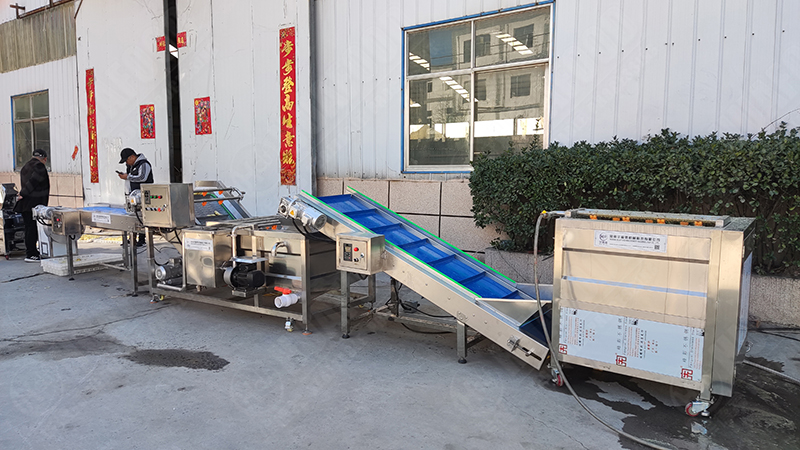

Lavando & Peeling

Lave as raízes de gengibre com uma máquina de lavagem de gengibre para remover sujeira e impurezas; Em seguida, use uma máquina de descasque para remover a pele externa do gengibre.

Fatia de gengibre & Secagem

Corte o gengibre em fatias finas e desidrate -o através de um secador. Os métodos de secagem comuns incluem secagem de ar quente ou secagem congelada.

Moagem

Moa as fatias de gengibre seco em pó fino usando um triturador.

Peneirando & Embalagem

Peneira impurezas através de uma máquina de peneira para garantir que a finura do pó de gengibre seja uniforme; finalmente, Use uma máquina de embalagem automática para empacotá -la para garantir a frescura do gengibre em pó.

Negócios de fabricação de gengibre em pó

A indústria de gengibre em pó teve um crescimento significativo nos últimos anos devido ao aumento da demanda por suplementos naturais de saúde, agentes aromatizantes, e medicina tradicional. À medida que a conscientização global dos benefícios de saúde de Ginger continua a aumentar, Os fabricantes estão aumentando a produção para atender à crescente demanda. No entanto, a indústria enfrenta vários desafios, incluindo qualidade inconsistente do produto, altos custos de mão -de -obra, e a necessidade de processos eficientes que reduzem o desperdício. Em muitos casos, Operações manuais levam a inconsistências no produto final, que pode afetar a satisfação do cliente.

Vantagens da linha de produção em pó de gengibre

Nosso linha de produção de gengibre em pó foi projetado para enfrentar esses desafios de frente. Automatizando os principais estágios do processo de produção, Reduzimos significativamente os custos de mão -de -obra e melhorar a eficiência. O sistema garante qualidade consistente do produto em todas as etapas, Da classificação à moagem, minimizar o risco de erro humano. Adicionalmente, Nossa tecnologia avançada de secagem e moagem garante que o pó final de gengibre mantenha seu sabor, aroma, e valor nutricional. Com nossa linha de produção, Os fabricantes podem ampliar suas operações sem comprometer a qualidade ou aumentar a complexidade operacional.

Conclusão

Para concluir, A linha de produção de gengibre em pó fornece uma solução simplificada e eficiente para os fabricantes de gengibre em pó. Se você está procurando aumentar a capacidade de produção, melhorar a consistência do produto, ou reduzir os custos operacionais, Nosso equipamento de última geração pode ajudar. Se você estiver pronto para aprimorar seu processo de fabricação de gengibre em pó, Entre em contato conosco online para uma cotação gratuita hoje e dê o primeiro passo para melhorar suas operações comerciais.

Máquina de lavar legumes

Máquina de lavar legumes

Whatsapp

Digitalize o código QR para iniciar um bate -papo do WhatsApp conosco.