L'automatique ligne de production de pelage à l'ail est spécialement conçu pour l'ail sec (faible teneur en humidité et structure solide). Il adopte un pelage à sec par flux d'air et un traitement sans eau tout au long du processus pour éviter que l'immersion dans l'eau n'affecte la qualité du séchage.. Il peut réaliser à grande échelle, faible perte, production automatisée à taux de pelage élevé, et constitue un équipement idéal pour les entreprises de transformation en profondeur telles que les condiments, poudre d'ail séchée, et gousses d'ail séchées.

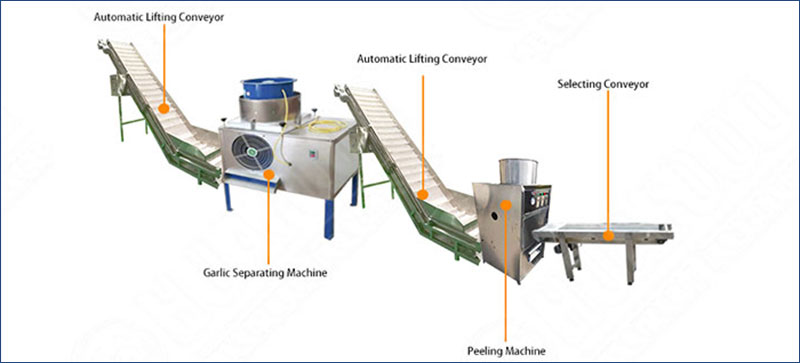

Séparation de la tête entière → pelage du flux d'air → nettoyage et dépoussiérage → traitement par interférence du flux d'air → séchage en profondeur → emballage

Machine de séparation de clous de girofle à tête entière: 304 acier inoxydable, sépare automatiquement l'ail séché en gousses indépendantes, traitement non destructif;

Machine à éplucher à flux d'air: technologie de pelage à sec à flux d'air comprimé, taux de pelage ≥95%, fonctionnement à sec;

Machine de nettoyage et de dépoussiérage: bulle en remuant l'eau lavage, élimination efficace de la poussière et des peaux éraflées;

Sécheur d'air: éliminer rapidement l'humidité de la surface pour préparer le séchage;

Séchoir: Ceinture en maille/air chaud/séchage micro-ondes, assurer une humidité ≤6 %, prolonger la durée de conservation;

Machine d'emballage: pesée automatique, remplissage d'azote/emballage sous vide, convient aux produits en poudre d'ail séchée et aux gousses d'ail séchées;

Contrôle par API, peut réaliser une gestion automatique du réseau.

304 matériau en acier inoxydable, conforme aux normes d'hygiène alimentaire.

Peeling à flux d’air entièrement sec, pas besoin de tremper dans l'eau, conception optimisée pour l'ail séché.

Matériau résistant et facile à nettoyer, faible coût d'entretien.

L'automatisation réduit l'occupation du travail et réduit la contamination humaine croisée.

Empêche la structure de l'ail séché d'être endommagée par l'humidité., vitesse de pelage rapide et haute efficacité.

Améliorer la capacité de production et l’uniformité du pelage, économiser du temps et du travail.

Réduisez les consommables et la fréquence de maintenance, excellent rapport entrée-sortie.

Le produit est sec et complet, avec une qualité stable, adapté au traitement de produits à base d'ail séché haut de gamme.

Le taux de pelage est stable entre 95 et 99 %;

Des cas réels montrent que l'efficacité de la production et de la transformation est d'environ 80% supérieur à la méthode traditionnelle;

Après séchage automatisé, l'humidité est réduite à ≤6%, et la durée de conservation du produit est augmentée à 12-24 mois;

Cette ligne de production d'épluchage d'ail séché entièrement automatique adopte une combinaison de processus d'épluchage par flux d'air, traitement sans eau, et un séchage efficace depuis la séparation des gousses jusqu'au conditionnement compte tenu des caractéristiques de l'ail séché, alliant haute efficacité, faible perte et assurance qualité du produit. Cela réduit non seulement les coûts de main-d'œuvre et de logistique, mais peut également produire de manière stable de la poudre d'ail séchée de haute qualité, gousses ou tranches d'ail séchées, vous aider à vous démarquer dans l'industrie mondiale des assaisonnements et de l'alimentation.

🎯 Contactez-nous maintenant pour laisser un message en ligne et nous indiquer votre capacité de production et votre préférence de forme d'ail séché. Nous vous fournirons des solutions personnalisées, tests d'échantillons gratuits et devis précis!

Machine à laver les légumes

Machine à laver les légumes

WhatsApp

Scannez le code QR pour démarrer un chat WhatsApp avec nous.