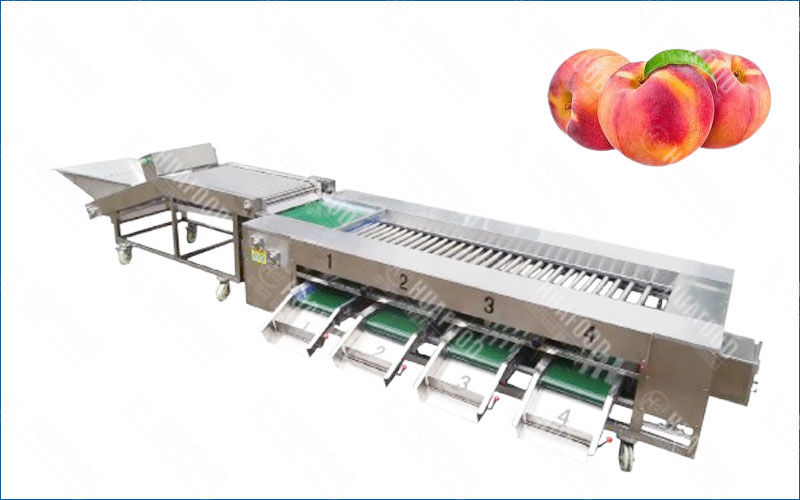

IL peach fruit size grading machine is specifically designed for peach sorting, we are launching this high-precision peach size grading machine. This equipment utilizes an advanced stainless steel roller conveyor and gap adjustment system to achieve rapid and accurate size grading of peaches of different varieties and ripeness levels. It not only efficiently handles this delicate and easily damaged fruit but also ensures a low damage rate and high consistency during the sorting process, making it an ideal core equipment for modern peach processing, confezione, and export enterprises.

Peaches are evenly fed into the grading area by a feed conveyor belt. The core of the equipment consists of a series of parallel stainless steel rollers with precisely adjustable spacing. As the rollers rotate, the peaches are conveyed forward. When a peach's size is smaller than the gap between the rollers, it naturally falls into the corresponding collection trough or conveyor belt. By progressively increasing the grading gaps, continuous, automated, multi-stage sorting of peaches from smallest to largest size can be achieved. The entire process is smooth and gentle, greatly reducing friction and compression damage to the peach skin.

Extremely High Sorting Accuracy and Consistency: Millimeter-level gap control ensures highly uniform peach size within each grade, significantly improving product appearance standardization and meeting the stringent standards of high-end markets and exports.

Extremely Low Fruit Damage Rate: Smooth rollers and a flexible design avoid sharp friction and hard impacts, making it particularly suitable for fruits like peaches that are sensitive to mechanical damage, maximizing fruit integrity and commercial value.

Superior Durability and Hygiene: All major contact parts are made of stainless steel, offering corrosion resistance, long lifespan, and easy thorough cleaning and disinfection. Maintenance is simple and complies with international food processing hygiene standards such as HACCP.

Flexible and Powerful Production Capacity: Quickly adjustable to adapt to different peach varieties and seasonal size variations, its powerful single-machine processing capacity easily meets peak production demands during harvest season.

Stainless Steel Roller Bar Grading System: The core grading component uses high-quality food-grade stainless steel rollers with a smooth, corrosion-resistant, and easy-to-clean surface, meeting food safety production standards.

Precision Adjustable Gap Design: The gap between each pair of rollers can be infinitely precisely adjusted via a central control system to accommodate the precise sorting needs of peaches of different sizes, from early-ripening small fruits to late-ripening large fruits, achieving grading accuracy down to the millimeter level.

Gentle Contact & Buffering Design: A specially designed buffer device in the conveying and transition areas ensures that peaches experience gentle force during contact with the rollers and during their descent, effectively protecting the peach's delicate skin and preventing bruising.

Automated Conveying Integration: Equipped with an automatic feeding, evenly distributed, and multi-channel discharge conveyor belt, it can seamlessly integrate with washing, essiccazione, and packaging lines to achieve continuous, high-volume operations.

Enhance Product Value and Profit Margin: Precise grading allows for the differentiation of high-quality, large peaches and their sale at higher prices, maximizing the market value of each peach and directly increasing your revenue and profits.

Strengthen Brand Reputation and Market Competitiveness: Supplying graded peaches of uniform size and perfect appearance significantly enhances your brand image, winning the long-term trust and orders of discerning customers (such as large supermarkets, exporters, and specialty fruit shops).

Significantly Reduce Labor and Operating Costs: One machine can replace dozens of skilled sorting workers, solving the problems of low efficiency, high cost, inconsistent standards, and fatigue associated with manual sorting, while also reducing long-term management costs.

Ensure Product Quality and Reduce Losses: Low-damage sorting means less post-harvest spoilage, estendendo la durata di conservazione, reducing waste caused by damage, and ensuring supply chain efficiency from the source.

In sintesi, this high-precision peach size grading machine (with stainless steel rollers) is a professional sorting solution specifically designed for the physical characteristics of peaches. It integrates high precision, low damage, Alta efficienza, and strong durability, effectively helping you solve peach grading challenges and achieve product value enhancement, cost optimization, and brand upgrading.

Take action now to optimize your peach processing flow!

If you would like to obtain more detailed technical parameters, capacity data, or customized solutions, please click to contact us or leave a message below. Our professional team will provide you with one-on-one product consultation and free quotation services, helping you move towards a new stage of intelligent and efficient peach processing!

Lavatrice per verdure

Lavatrice per verdure

WhatsApp

Scansiona il codice QR per avviare una chat whatsapp con noi.